Many times when we start with 3D printing we find different problems that can give us many headaches. The most common are warping and cracking, problems that arise with the ABS filament, especially with ASA, not with the rest of 3D filaments. But exactly what are they? and most importantly, how can we avoid them? At Winkle we want to solve your doubts and help you so that your 3D prints are what you imagined.

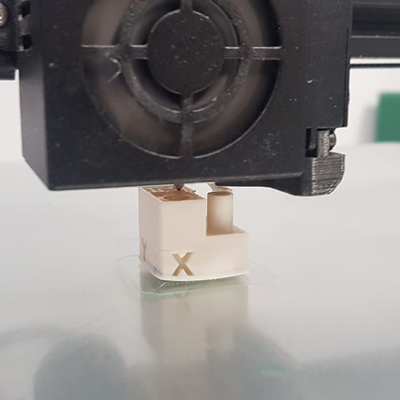

Warping occurs when the pieces we print detach from the base and curl upward. But why does this happen? It is because the layers are cooling on top of others and, when contracting, they pull the material upwards. It is a problem that we can easily find when we 3D print by extrusion with thermoplastics, especially if we print large parts.

There are a lot of tricks to avoid wrapping:

- Use a heated bed, this way it will always be easier to control the first layer of your prints. If your 3D printer already has it and you are still having problems, raise the temperature by 5 or 10 degrees.

- Having a good room temperature, in other words, printing in a place that is not very cold and does not have currents will help you avoid warping and, if you also surround the 3D printer with a box or casing, the result will be much better.

- A good calibration of the 3D printer. If you don’t have it calibrated and you print the first layer very high, it will come off the base.

- Review your fixing product. The fixer you use may not be the most suitable for your 3D printing material and that is why you may have worse results.

- Make the first layers thicker and slower than the rest of the print, this way the cooling will be slower and it is more difficult for the ends to lift.

- Modify the printing position, better to place the piece vertically than horizontally when it is large, since the surface of the first layer is reduced and the result is better.

- Making ears or brim to the piece, add adhesion surface to the bed that helps to avoid warping.

Cracking is similar to warping, except that instead of appearing in the first layer of printing, it appears in the intermediate layers. Normally the pieces that have this problem tend to undergo warping in the first layer. The solutions for this problem are simple: you have to maintain a warm room temperature, closing the 3D printer, and achieve a high extrusion temperature so that there is good adhesion between the layers. With these tips you will get a 3D printing without cracking.

The quality of the 3D filaments you use is also very important, the higher the quality, the more complicated it will be for problems such as warping or cracking. At Winkle we offer you a wide variety of 3D filaments so that you can get the 3D prints that you have in your head. If you have any questions, consult our website winkle.shop or contact us so that we can advise you on which 3D filaments are the best for your project. At Winkle we continuously work to offer you new 3D filaments so that your creativity in 3D printing has no limits.