ABS filament or Acrylonitrile Butadiene Styrene is used for the manufacture of a multitude of products from LEGOs to musical instruments through piping systems, medical devices or carpentry panels. This is because it is a very resistant, lightweight and relatively inexpensive material, making it one of the most widely used plastics in the industry.

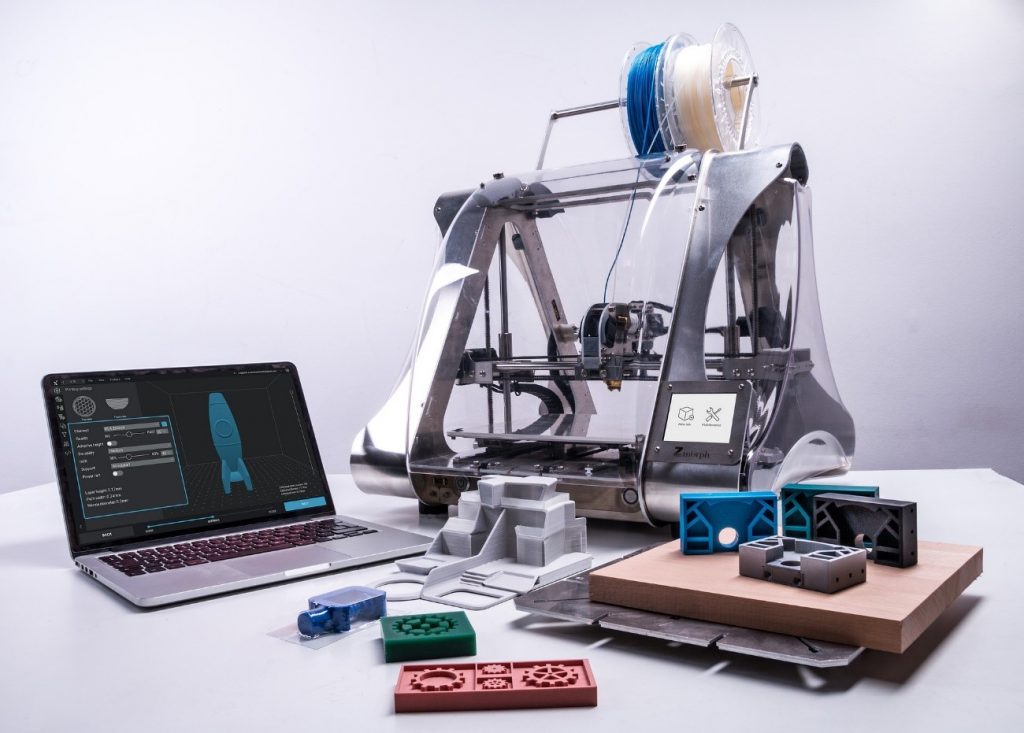

In the world of 3d printing, ABS filaments are widely used, second only to PLA filaments, used together in this type of printing. This is because it is a material that melts and cools without altering its properties, which makes it ideal for use in 3d printing. But what other qualities does it have?

- It is a very resistant material (scratches, heat, chemicals) and has great durability. It is the 3D printing material that best withstands heat and pressure, so it is difficult for it to break during printing.

- It gives very good printing results, as long as it is set up correctly and done at the indicated temperature.

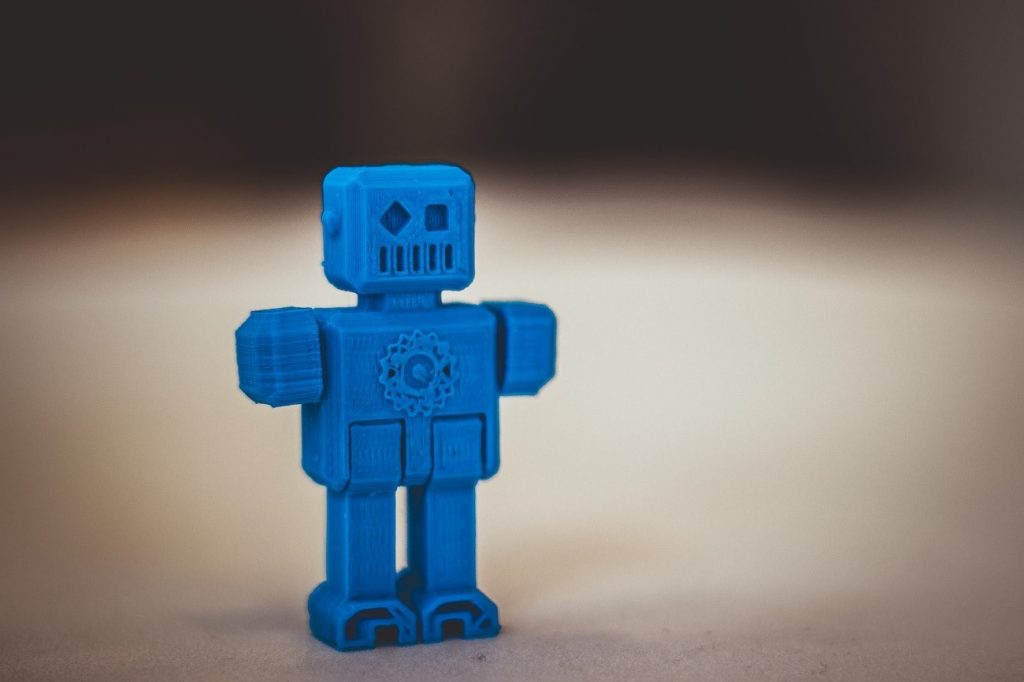

- The pieces made with this material can be sanded and manipulated, in addition to being glued with acetone. They can also be painted with acrylic colors.

Although this type of filament has a number of drawbacks:

- The temperature at which it should be printed must be correct and cool slowly, otherwise the adhesion between layers would not be optimal.

- There may be problems with shrinkage between layers and cracking (cracking effect) if the environment is too cold.

- There may be shrinkage at the corners of the part (warping effect).

As we have already seen, ABS filaments within 3d printing are recommended when physical properties related to resistance to impact and high temperatures are required. In addition, it has a wide assortment of colors. At present, other types of ABS filaments are emerging to which additives are added to modify their properties and improve problems such as warping. For example, there are ABS with aramid fibers that reduce deformation.

At Winkle we have two types of high quality ABS:

- ABS HF, has a great ease of 3d printing and is much faster, since, thanks to its additives, it improves warping and cracking, achieving greater flexibility in the final pieces.

- ABS HI, has a great ease of 3d printing since, thanks to its additives, it avoids warping and cracking. In addition, the printed parts have a higher resistance to impact.

Therefore, although other types of materials are currently emerging for 3d printing, ABS continues to be one of the best-selling products for this use, evolving with new additives that solve printing problems. If you have any questions about which products to use, check our website. In it you will find the product you need to start creating.

At Winkle we continue to research to put high-quality products with the best features in your hands so that you get an excellent 3d printing.